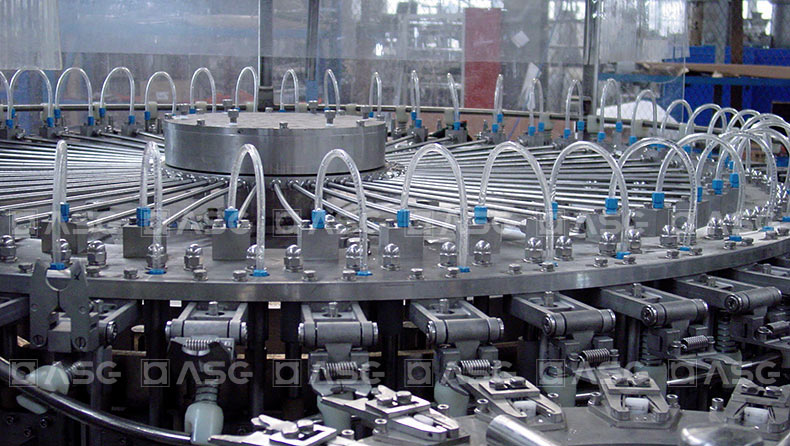

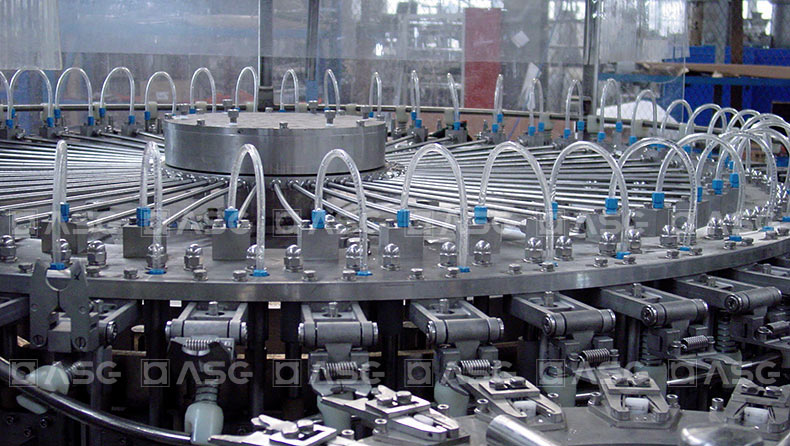

Sports Drink Filling Machine Production Line

Sports drink filling line is a 3-in-1 filling machine, combined with rinsing, filling and capping. Sports drink production line is innovated and designed in the requirement of still juice, tea, sports drinks, sports beverage on the bases of introducing, digesting and absorbing advanced technology from Germany.ASG Machinery have completed the design and manufacture and installation of a complete set of sports drink filling production line for China’s jianlibao.The current beverage filling machine is stable in China.We are an excellent beverage filling machine manufacturer in China.

Sports Drink Filling Line Description:

Small Scale Sports Drink Filling Machine Production Line.

The whoe filling line can fill carbonated drink/soft drinks into PET bottle/Glass bottle with automaticly working, sports drink production line can fill from 300m-2000ml bottle with same cap diameter, the filling machine adopt Isobaric filling type to control the co2 content of water.

Bottle Infeed of Sports Drink Filling Line

Bottle infeed by combination of infeed starwheels.

Equipped with bottle jam protection device.

Bottle Rinser of Sports Drink Production Line

1.The rotary wheel is a fully stainless steel welded structure.

2.The machine applies unique overturning bottle clamp, which is an innovation of our company. This bottle clamp grips bottle at neck position, avoiding bottle mouth thread contamination caused by rubber gripper block of a traditional bottle clamp. Made of SUS304 stainless steel, this bottle clamp is hygienic and durable.

3.The high efficiency atomizing spay nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and also saves rinsing water.

4.All sliding bushes of lifting device use Igus (Germany) anti-corrosion maintenance free bearing.

5.The rinser is driven by driving system positioned inside machine frame via gear transmission.

6.Made of stainless steel of superior quality.

7.Equipped with bottle jam protection device.

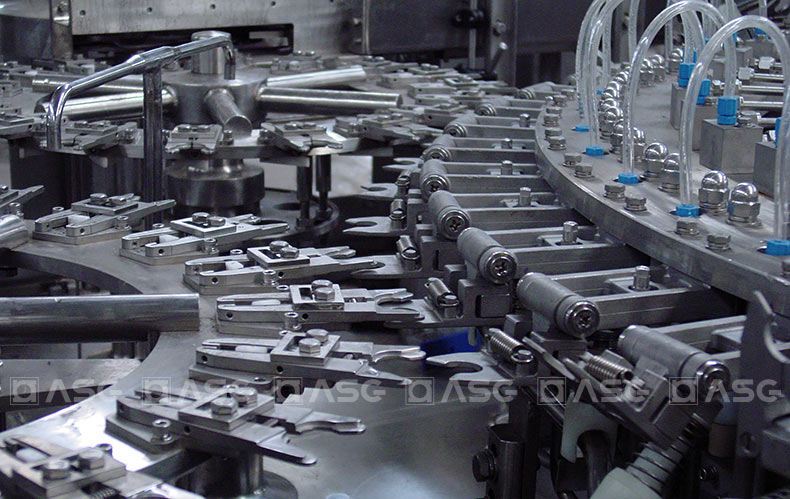

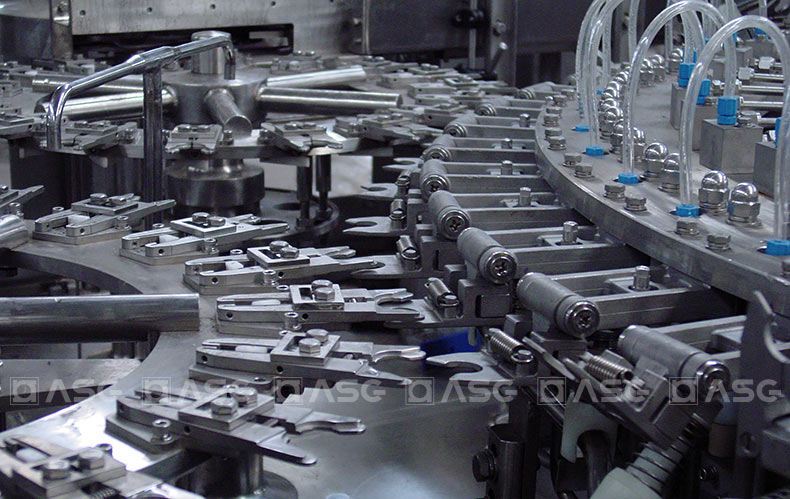

Bottle Filling of Sports Drink Filing Equipment

The design of filling structure is reasonable and hygiene dead angle, the run of equipment is stable, it can control the material from the bottleneck, the control accuracy is within ±2mm.

The filling valve material is SUS304

The filling system has liquid level automatic control.

Filling valve lift is controlled by the valve elevator, after filling valve contact the bottleneck ,it start to fill.

Bottle is conveying by the wheel in the filling part.

The juice or other hot beverage can be backflow by return tank to control filling temperature.

Bottle Capping of Sports Drinks Filling Machine

1.It import of advanced technology of screw capping, improve the stability and reliability of the screw capping machine. The magnetic torque is used for screw capping. the power of screw capping can be adjusted without steps. The power of the screw capping can also be fixed, and the caps will not be damaged, the capping is reliable.

2.In the screw capping part. it installed photoelectrical control , when it has no cap ,or the cap is bad, the machine will stop automatically.

The complete line includes:

A. Automatic Water Treatment System ( Reverse Osmosis System For Pure Water/Hollow Fiber Filter For Mineral Water)

B. Automatic PET Bottle Blowing Machine ( Blowing PET Prefroms to be empty PET Bottle)

C. Automatic Carbonated Drinks Pre-Mixing System (Pre-mixing and sterilizer syrup/co2/water and other additives)

D. Automatic 3 in 1 Carbonated Drink Filling Machine ( Rinsing Filling Capping 3 in 1 into functions in one machine)

E. Automatic PVC Shrink Labeling Machine ( Shrink PVC Labels on bottles)

F. Automatic Ink Jet Printer (Put date/time on bottle)

G. Automatic PE Film Shrink Wrapping Machine ( Packing filled bottles to be 4*6/4*5/3*4 etc by PE Film)

Introducing – Sports drink filling line:

Automatic Water Treatment System

— All adopt food grade SUS304 material to manufacture,need customer supply raw water quality report

— Includes Raw water tank/raw water pump/silica sand filter/active carbon filter/inhibitor dosing unit/precision filter/RO or Hollow fiber filter/UV Sterilizer/Ozone sterilizer/Ozone tower/Storage water tank/Pipe and Valves.

Automatic PET Bottle Blowing Machine

— Used for blow pet prefroms to be empty PET bottle for filling.

— We can make bottle mould as your bottle design(bottle layout)

— Bottle blowing main machine/auto preform loader/high pressure and lower pressure air compressor/air tank/cooling dryer/air filter/bottle mould

Automatic Carbonated Drinks Pre-mixing System

— The machine is used for mixing co2 with syrup/water together, it ‘s necessary machine for making carbonated drinks. The co2 contain gas can reach internation standard.

— The system includes many machines to mixing syrup/water/co2 and other additives,each machines connected by SUS pipe to supply mixed carbonated drinks to filling machine for fill.

Automatic 3 in 1 Carbonated Drinks Filling Machine

— Rinser Filler Capper 3 functions in one unit (different capacity with different filler valves)

— Includes empty bottle feeding air conveyor/rinser filler capper/auto cap loader/filled bottle out conveyor/PLC programe/Touch screen

Automatic PVC Shrink Labeling Machine

— Main for Shrink PVC labels on bottle by steam.

— Includes bottles transfer feeding conveyor/shrink labeling machine/shrink heat tunnel/steam generator/out conveyor

Automatic Ink Jet Printer

— Used for put the dates/times on bottle

Automatic PE Film Shrink Wrapping Machine

— Used for packing filled bottles to be 4*6/3*4/2*3 packer by PE film

Buffer Conveyor

— In casef bottles overturned due to high capacity,it needs buffer conveyor for connect whole line

— The buffer conveyor is confirmed by customer’s factory layout (L*W*H)