- Home

- Products

- Water Filling Machine

- Water Bottling Machine

- Juice Filling Machine

- Tea Fillers

- Carbonated Beverage Equipment

- Soda Filling Machines

- Condiment Filler

- Can FIlling Machines

- Blowing-Filling-Capping Combi Block Machine

- Water Treatment System

- Filling System

- Pet Bottle Blowing Machine

- Downstream Packing System

- Pretreatment System

- Conveying System

- About ASG

- Solution

- Beer Filling Machine

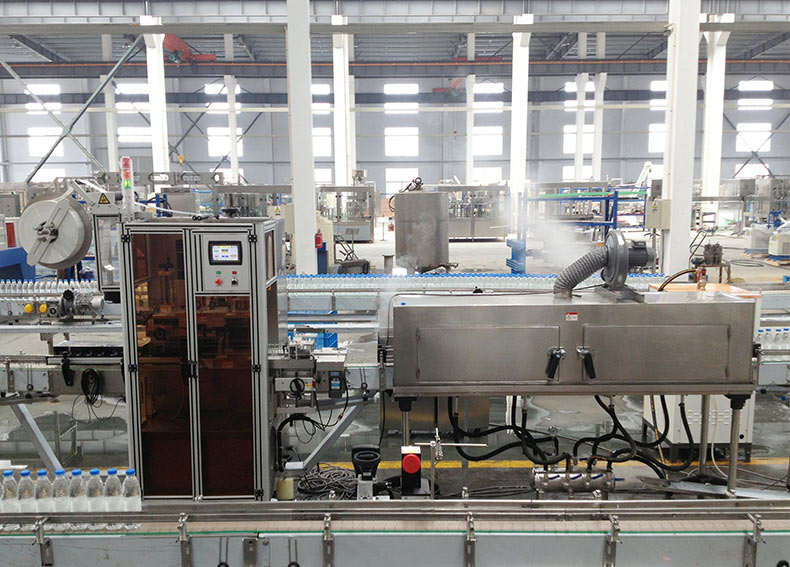

- Bottled Water Filling Machine

- Carbonated Beverage Production Equipment

- Coca-Cola Bottling Production Line

- Condiment Filling Machine

- Daily Chemical Packing Machinery

- Drinking Water Filling Machine

- Juice Filling Line

- Non-gas Beverage Filling Machine Line

- Pure Water Filling Line

- Tea (Milk) Drinks Filling Machine

- Water Bottling Line

- Water Bottling Plant

- News

- Service

- H&R

- Contact