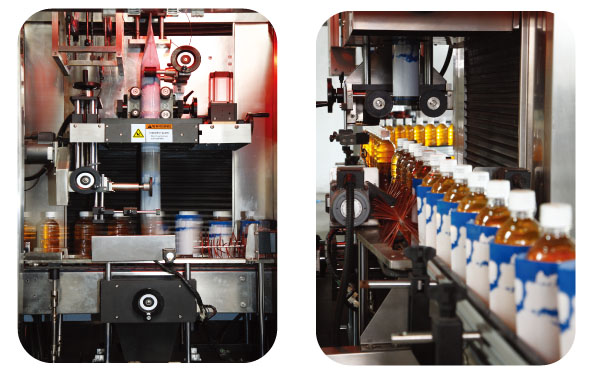

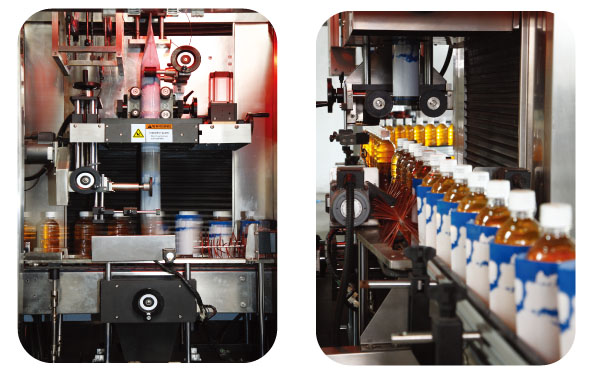

Equipment profile:

Making research and development of label sleeving machine, adhesive labeling machine, packing machine, PE film packaging machine by our company is equipped for all kinds of bottle type of fruit juice, tea drinks, dairy products, pure water, condiments, beer, sports drink, food and beverage industry. Company people-oriented, strengthening internal management, to carry out the production of the best spirit, To customer demand as the goal, Production for the customer satisfactory equipment, we are good partners with Yili Group, MENGNIU DAIRY, little foreigner dairy, Uni-President Group, Harbin pharmaceutical group, and Danone Group etc.

Electric appliances are all imported high quality brand, such as: Germany’s Siemens, Japan Mitsubishi, Japan YASKAWA, Japan Panasonic,etc.

Driving unit:

Synchronized transmission and drive by gear with one belt. The change of transmission belt will be finished quickly.Compared to the type of traditional multilayer whose change and maintain need more than six hours,its maintenance is easy and maintain is simple,so it doesn’t influence production.

Cutter head unit:

The new style cutting knife drived by servo motor, with high speed, more stable and precise, shrinks perfectively. Synchronouslocating device enables the tolerable error to 1mm.Unit cutter head plane design in China which applies to the container of ∮30mm—∮130mm.You never need to change or debug it.Cutter head original transducer is inside the cutter head and when you take down cutter head, you do not need to correct the synchronous belt. It also has unique light touch human-machine screen,that means,auto search original location as well as safety and convenience which is ahead of other congener products.

The new design of cutter adopt step motor with high speed, stable and exact movement, trim cut place and perfect shrink. Compatible with the label synchronous location structure, the error of cutting place is within 1mm.

Label feeding unit:

Singlematerial shelf with reasonable height in order to make it convenient to install label. It adopts rotary potentiometer which enable the label feeding stable and fluent and avoid the error label length, label block and other problem when label feeding servo convey the label. It will stop automatically and give alarm light and also display on the touch screen.

Clean down unit:

Adopt with motor coordinating with double circular arcsynchronous belt makes clean down plastic core-rubber-tires synchronously and ensures the label casting stably

Bottle carrying system:

Adopted with mechanical transmission to drive the positioning belt on both sides. While changing the whole bottle carrying unit, the down and up, width are all controlled by one hand wheel aiming to synchronously and swiftly adjust.

Machine head up and down unit:

It adopts motor to up and down which enable the operation more convenient.

New Steam shrinkage furnace:

Thermal shrinkage greatly improve the efficiency, adjustment, easy maintenance, shrinkage level off, the steam jet way using drum design type, pipe flow does not occupy a space, blower each edge is divided into four sections, each section of high and low, and the volume before and after adjustment, respectively, to achieve the most perfect contraction effect. Low pressure steam drum adopts the design of seamless steel pipe, all over using stainless steel hose fast connector, remove, installation is convenient. Shell of the machine is made of stainless steel and heat preservation, not only save energy, and approved to international safety standards, at the bottom of the stainless steel water pans concentrated condensed water, can take over discharge, working environment is not affected, casing window before and after the two attached. Adding pour bottles of guide bar on both sides, which can effectively avoid shrinking in furnace wall. The whole machine adopts the waterproof design for stainless steel structure, convenient operation and maintenance.

New type hot air furnace type contraction, the use of high pressure fan, special hot shrink ring duct more energy efficient, shrinkage effect, traditional bottle, if furnace can’t contraction curve by this hot air furnace can get satisfaction of flat contraction effect (optional).

Technical parameters:

The host end fittings:

Round bottle labeling machine. For round bottle labeling, can use attachment; Conveyor belt is high-speed flat belt and conveyor belt width is 110 mm, conveying speed 0 ~ 26 m/min

Base: adjustable heightconveyor belt from the ground , from 610 to 1010 mm, applicable in different workplace or assembly line interface. Suitable for samples: standard is suitable for round bottle label.

touch screen: model( TP170A ) origin( SIEMENS )

output module: model( EM232 ) origin( SIEMENS )

stepper motor: model( TS3630N2E3/1.4A )origin( Japan)

Check the electric eye model( WF2-B4210 )origin( SICK )

Seized electric eye model( VRF-N ) origin( SICK )

performance characteristics:

Power Supply:one-way communication220V±2% , 50/60Hz , The whole machine power about1000W。

Dimensions:1.45M(L)*0.75M(W)*1.55M(H)。

Structural materials:SUS303/304stainless steel6061/6063aluminium alloy。

Conveyor belt specification:110mm(W)*2.2M(L)。

Conveyor Height:can adjust between0.75M-1.05M

Put line speed:0-26m/min(The speed synchronization with conveyor belt)。

LABEL WIDE:10~130mm,:15~300mm (Can design according to customer’s request)

Posted content high:10~230mm (Can design according to customer’s request)

Very large touch screen, simple operation

Apply paper roll diameter:φ76mm, Roll Outside Diameter:φ350mm

Labeling Precision:error of Before and after between ±1.0mm;up-down error between ±1.0mm

Labeling parameter on memory:10 group。